1

/

of

16

Projen Taiwan - Auto Tools, Hand Tools manufacturer

CA770005 24T Adjustable Torqe wrench push-through

CA770005 24T Adjustable Torqe wrench push-through

Adjustable torque wrench

24T industrial torque wrench with ±4% accuracy in both CW & CCW directions. Flexible operation with a wide torque range of 10Nm - 980Nm. Adjustable torque settings for various applications.

Manual Download Here

Feature:

- 24T. Industrial application.

- Direction & Accuracy: C.W. ±4% / C.C.W. ±4%

- Easy and flexible operation of design.

- A variety of types and wide torque range of choice.

- Torque range: 10Nm - 980Nm (10ft.lb - 700ft.lb).

- Torque setting types: Adjustable torque type

Packaging:

- 1pc/Blow Mould Case

OPERATION MANUAL

BEFORE STARTING:

- Study this instruction before use.

- This torque wrench is calibrated and tested before leaving the factory, it is certified to meet the current standard specification and has an accuracy of C.W. ±4% / C.C.W. ±4%.

- THIS TOOL IS A PRECISION MEASUREMENT AND DESIGNED FOR MANUAL TIGHTENING FASTENERS ONLY.DO NOT USE IT AS A NUT BREAKER OR FOR ANY OTHER PURPOSE.

- Do not over torquing the fastener, or it will cause tool’s damage and serious injury.

- Do not use this tool near rotating machinery.

- Disassemble this tool or make any adjustments will result in the loss of accuracy and invalidating the warranty.

- Do not continuously apply force after hearing the clicking sound or feel shock.

- Do not use any kind of extension on the handle of the tool. This will not only damage the tool, also affect the accuracy.

- Do not immerse grease inside ratchet head. It may cause unexpected damage.

- Use special care at minimum torque setting.

- Please wear gloves and goggles when working.

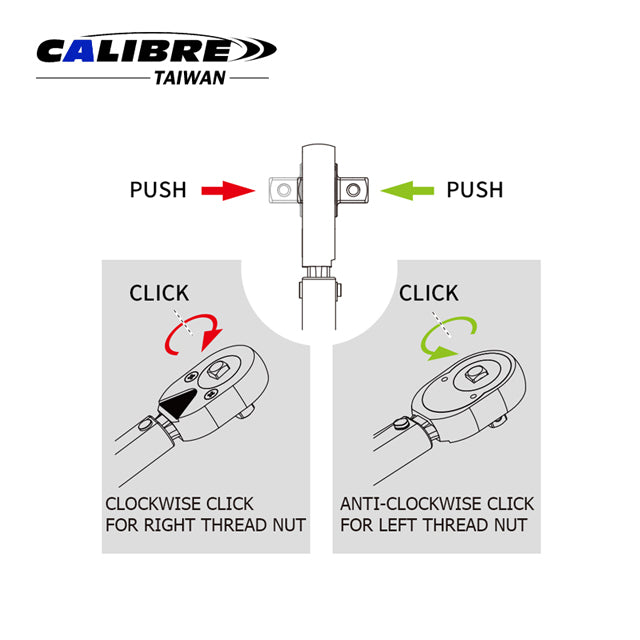

HOW TO USE:

HOW TO SET TORQUE VALUE:

- Pull the lock ring to unlocked.

- Turn the adjustable handle clockwise or counter-clockwise (Right or left) to set the desired torque.

- Push the lock ring to set finished.

-

For example:

To set torque to 135 Nm. Firstly pull the lock ring and turn the handle clockwise until the upper edge to130 Nm (see A) and the reading “5” on the long tube must align with the center line of scale vertically so as to acquire 130+5=135 Nm. (see B)

MAINTENANCE AND STORAGE:

- Please return torque value to the lowest reading when not in use. (see C) Do not turn below the lowest reading.

- If this tool has not been used for a period of time, it shall be preloaded several times at its maximum torque setting. This will allow internal lubricant to recoat.

- Clean this tool by wiping with a clean cloth after operation and storage in a dry environment. Do not dip any type of liquid in this tool. This may damage the internal of this tool.

- This tool should be recalibrated a period of 12 months, or 5,000 cycles, whichever occurs first.To contact with local vendor or an authorized repair center for supporting.

TORQUE CONVERSION FACTORS

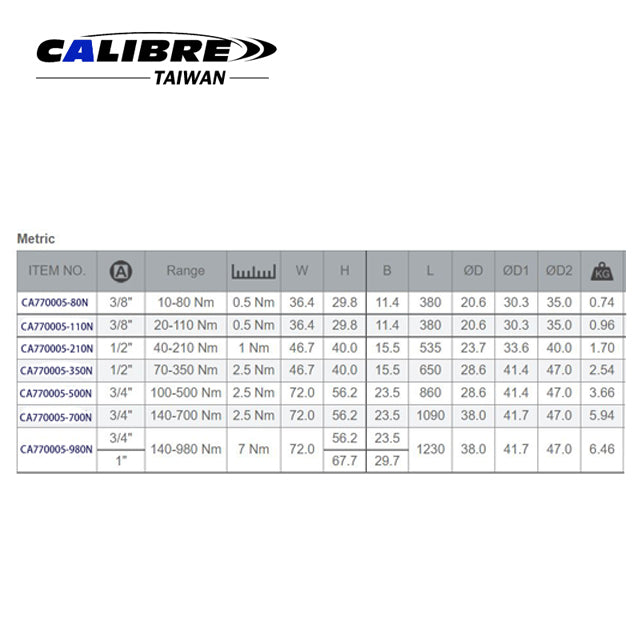

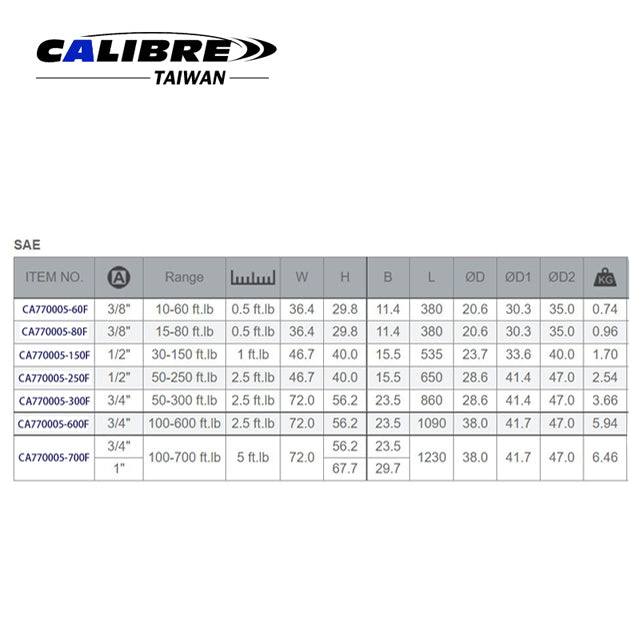

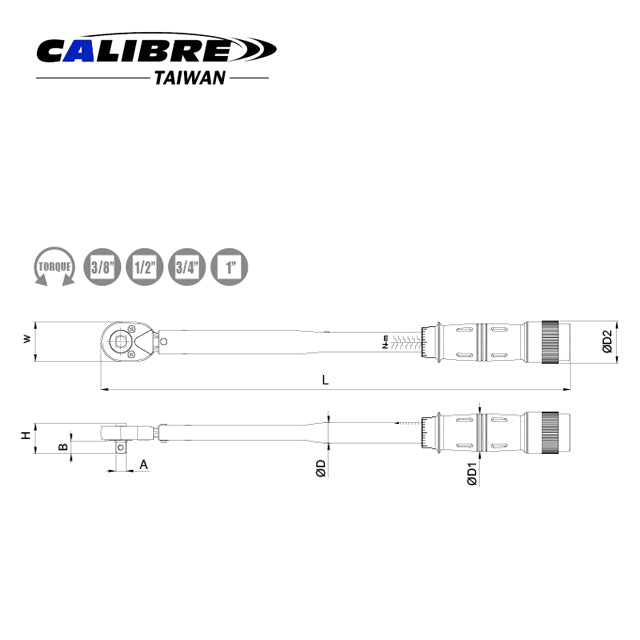

SPECIFICATION

Couldn't load pickup availability

We are also good at

-

New Arrival

Discover top-rated automotive tools and mechanics tools at Projen Tools. The best...

-

Automotive Tools

high-quality auto repair tools with competitive factory-direct pricing. Custom branding available. Your...

-

General Tools

Auto tools, specifically general tools, are essential for performing a wide range...